Bent shaft andwear defect detected in a belt-pulley driven fan

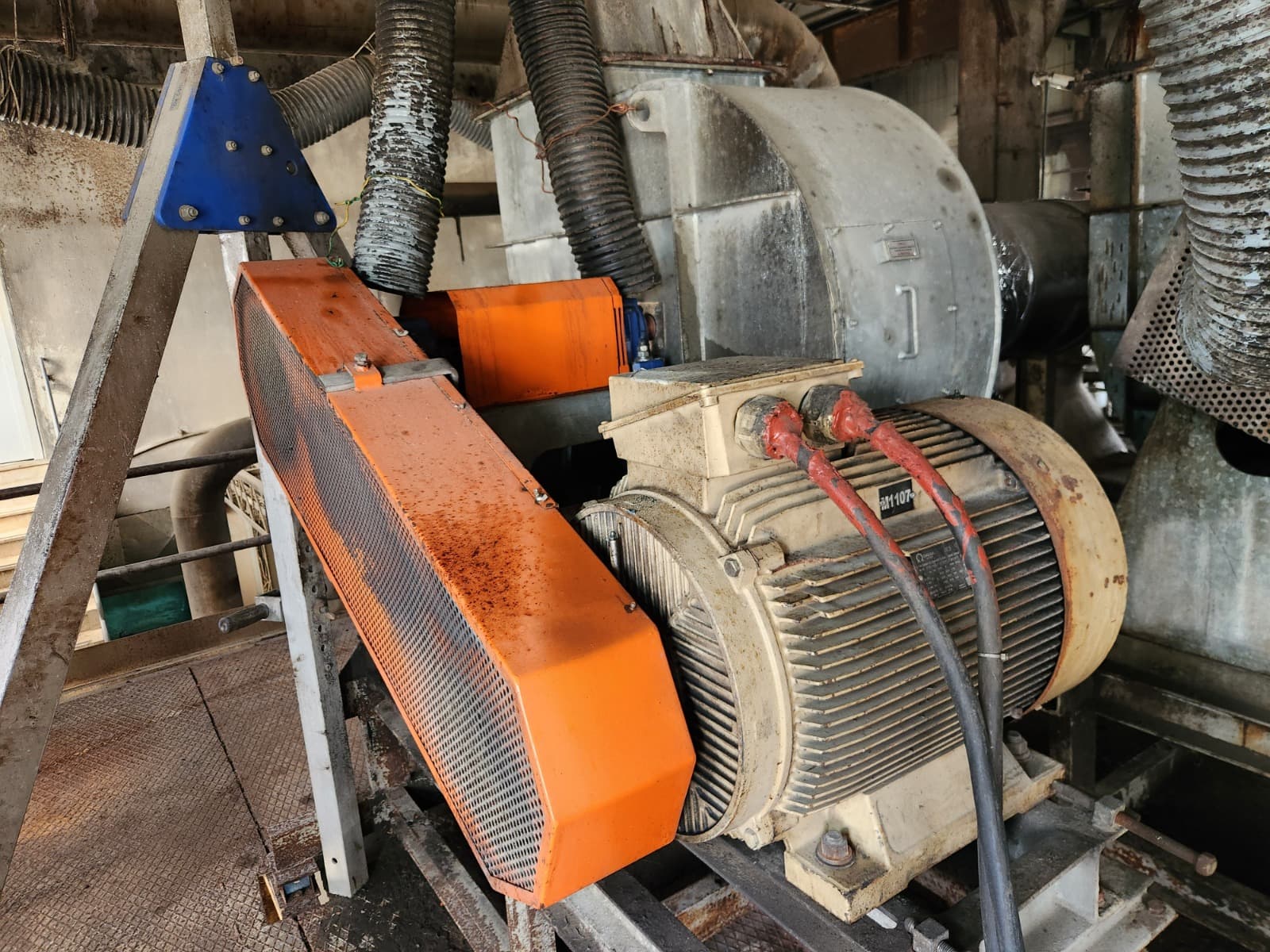

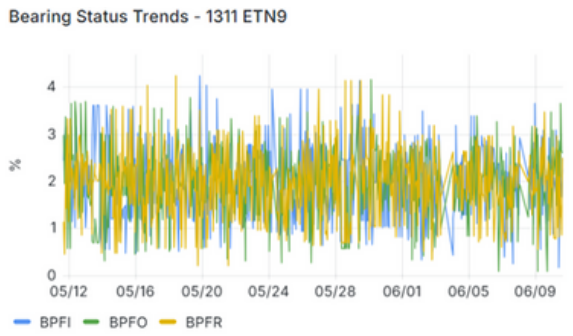

Figure-1: 3-axial vibration data was collected at a hourly basis from the pulley side bearing of this vacuum fan.

CASE STUDY

Asst. Prof. A. Kubilay Ovacıklı

1311 ETN9 type self-aligning ball bearings are suggested where pulley alignment is critical or in applications where there is a possibility of curvature in the gearbox shafts.

As can be seen in this fault, it has been determined that the real problem is not caused by the bearing, but by the runout in the shaft and the pulley gap it creates. Early detection of such faults through vibration analysis plays a crucial role in preventing unplanned downtime and reducing maintenance costs.

The fan shown in Figure-1 is located at a paper mill and it is monitored 24/7 and subjected to autonomous (unmanned) vibration analysis by ABLE System, the online machine health monitoring solution that was developed by ASCRIBO. For the early detection of mechanical faults that may occur in motor and fan bearings, pulleys, fan blades and shaft; 3-axial vibration data were collected on a hourly basis and autonomously analyzed via academically proven, unsupervised learning algorithms, developed by ASCRIBO.

This technology offers a more advantageous solution than traditional methods, as a statistical signal processing tool that does not require human intervention and is particularly suitable for working with MEMS sensor data, to detect damage in rotating machines at an early stage.

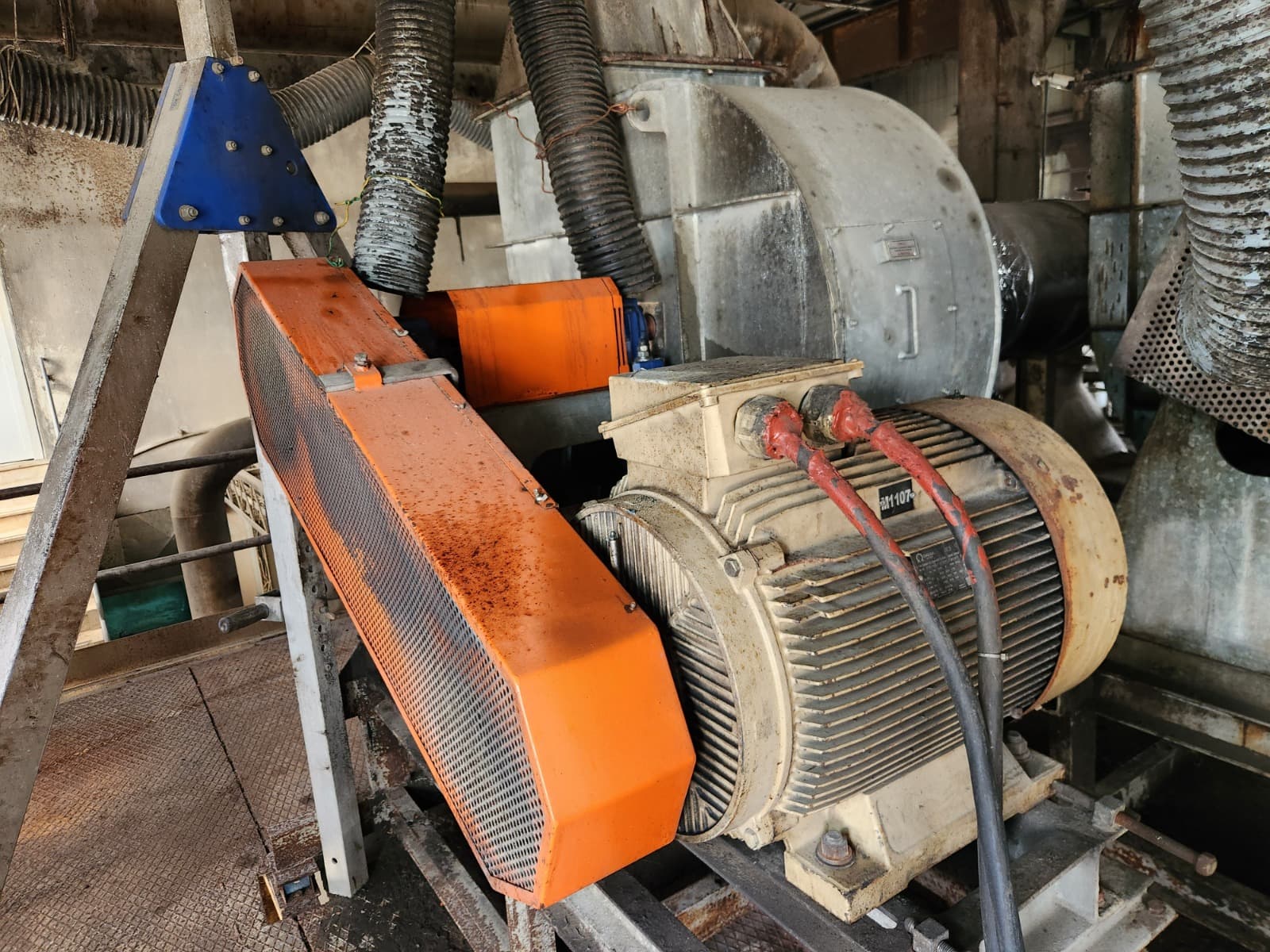

Figure-2:: While the overall vibration level in the fan pulley side bearing was at a level in-between 10-15 mm/s, a systematic increase was observed in the vertical axis which reached up to the levels of 20-25 mm/s.

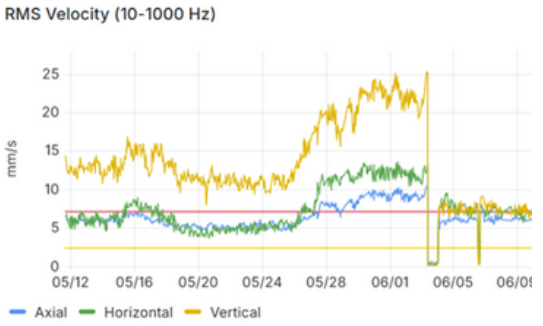

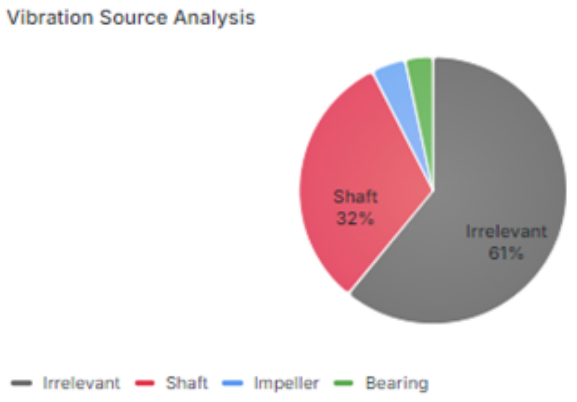

With increasing OVL (mm/s) in the vertical axis observed in the equipment; the possibility of shaft oscillating and/or bending due to loss of diameter, possible wear in the bearings and out-of-tolerance gaps that may occur in the bearings were evaluated as the possible causes. Among these possibilities, data supporting shaft wear and runout failure were obtained from the fact that no failure development was observed in any of the bearing subcomponents and that shaft-sourced vibrations were dominant in the ‘’Vibration Source Analysis’’ of the ABLE System, which has component-specific analysis capability.

Later on, the equipment was taken into maintenance, and as a result of the maintenance, the diagnosis was found to be correct and reported as follows.

Figure-3 Lack of an increase in bearing failure trends, also supported the idea that there may be runout in the shaft.

Figure-4: As can be seen from the ‘’Vibration Source Analysis’’ graph, the distribution rate of the vibration signal is at 32% for the shaft and is observed to be dominant compared to the bearing and fan blades in the overall distribution.

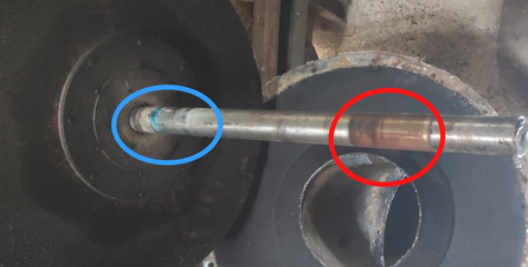

Figure-5: After disassembling shaft in the equipment that rotates at 3000 rpm, traces of wear caused by runout are seen at two end points.

As mentioned earlier, it was determined that the shaft might be running out. When the equipment was disassembled during planned maintenance, wear marks were observed at both ends of the shaft, confirming the diagnosis. The pulleys, shaft, and bearings were replaced. Following the replacement, a decrease in the overall vibration level (mm/s) was observed.

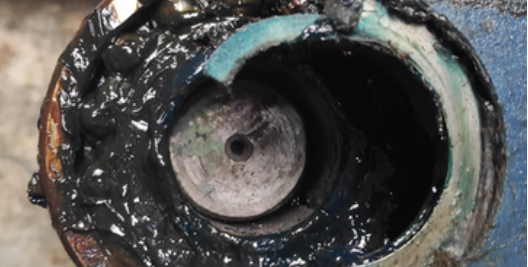

Figure-6: Due to the shaft runout, the bearing was strained and oil deterioration was observed. After washing and cleaning, no roughness or burring was detected on the rings.

Headquarters

11417 IRVING PARK RD IL-19 Suite B 13-7 FRANKLIN PARK, ILLINOIS 60131-3882 USA

+1 (224) 5810017