Support bearing failure due to imbalance in a belt-driven fan system

Figure-1: The bearing housing on the pulley side of the vacuum fan from which vibration data was collected in 3 axes at 60-minute intervals.

CASE STUDY

Asst. Prof. A. Kubilay Ovacıklı

1311 EKTN9 type self-aligning ball bearings with tapered bore are recommended for applications where pulley alignment is critical or there is a possibility of shaft misalignment on fast-rotating reducer shafts.

As will be seen in this failure, the root cause was determined to be an imbalance in the fan rotor, and it was found that this static force eventually degraded the bearing on the pulley side, where the moment due to imbalance is higher. The early detection of such failures through vibration analysis plays a critical role in preventing downtime and reducing maintenance costs.

The fan shown in Figure-1 was subjected to autonomous vibration analysis as part of predictive maintenance practices applied via the ABLE System, developed by ASCRIBO, at a white paper production facility. To enable the early detection of mechanical failures that could occur in the motor and fan support bearings, pulleys, fan blades, and the shaft; triaxial vibration data was collected and autonomously analyzed every 60 minutes using academically-proven, unique, unsupervised learning algorithms of the ABLE System. This technology offers a solution that is more advantageous than traditional methods, functioning as a statistical signal processing tool that requires no human intervention to detect damage in critical equipment at an early stage. It is particularly suited to work with low-bandwidth MEMS sensor data.

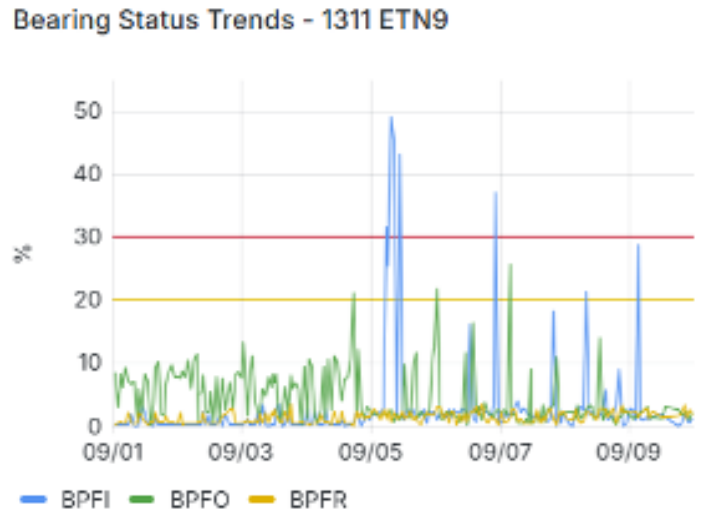

Figure-2: Inner race fault trend, horizontal axis.

Figure-2 shows the trends for the outer raceway (Ball Pass Frequency - Outer Race; BPFO), inner raceway (Ball Pass Frequency - Inner Race; BPFI), and ball (Ball Pass Frequency - Rolling Element; BPFR) fault frequencies, which were individually detected and tracked in the frequency spectrum resulting from the autonomous analysis of each raw data taken from the equipment.

Examining the trend for the horizontal axis reveals that an advanced-level fault developed on the inner raceway. Notably, this fault was detected independently of varying speed and load.

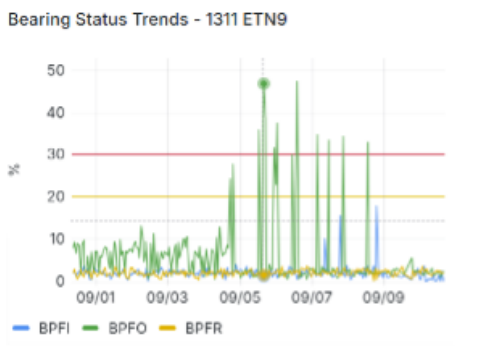

Figure-3, this time for the vertical axis, shows that an advanced-level fault developed on the outer raceway and could be detected independently of varying speed and load.

These findings were observed and confirmed as scratches and pits, as well as distributed defects, on the replaced bearing. Potential wear on the bearing housings and the possibility of excessive clearance in the bearing were also considered.

Figure-3 Outer race fault trend, vertical axis.

The equipment was subsequently taken down for maintenance, and upon inspection, the diagnosis was confirmed to be correct and reported as follows.

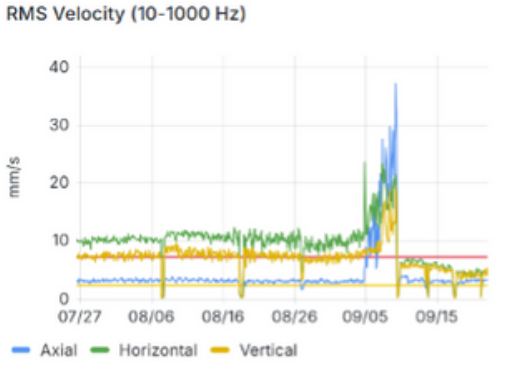

Figure-4: While the overall vibration levels at the fan's pulley-side bearing housing were fluctuating around 15-20 mm/s, a systematic increase was observed on all three axes after a specific date, rising to levels of 30-35 mm/s. Following maintenance, the levels dropped below the danger limit on all axes.

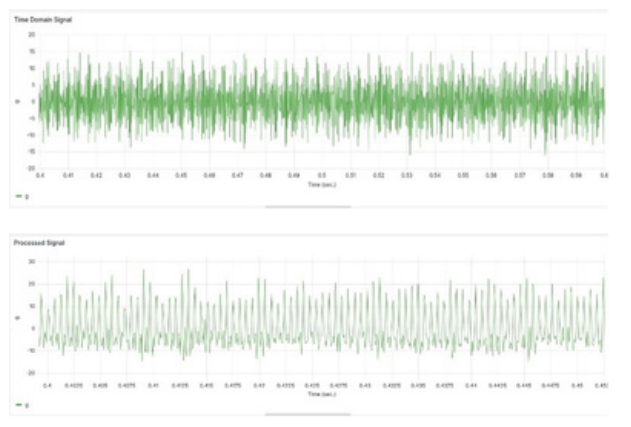

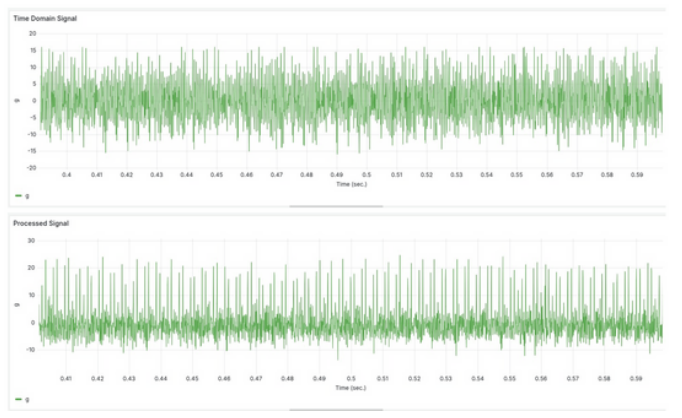

Figure-5: Raw data from the horizontal axis versus the signal processed via unsupervised learning algorithm of ASCRIBO. Faultrelated components that are not visible in the raw data became apparent in the processed data, and their accuracy was confirmed, along with the determination of the fault severity, through frequency analysis.

Figure-5 shows the raw and processed data from the horizontal axis related to the bearing fault in the housing.

While periodic impacts indicative of a bearing fault cannot be observed in the noisy raw data, the impulsive components caused by the outer raceway fault become visible in the data processed using unsupervised learning.

Considering that the fault had spread over a significant portion of the raceway surface—resulting not in short, isolated shocks, but in more frequent, weaker, and overlapping (superimposed) impulses due to multiple ball pass events occurring simultaneously—the mathematical complexity of making inferences from data acquired by low-bandwidth accelerometers, such as MEMS sensors, becomes apparent.

Figure-6: Vertical axis raw data versus unsupervised-learning processed signal. Frequency analysis confirmed the identity and severity of fault components revealed by the processing

Figure-6 shows the raw data versus processed data from the vertical axis, related to the bearing fault in the housing.

While periodic impacts indicative of a bearing fault cannot be observed in the noisy raw data, the impulsive and modulated components caused by the inner raceway fault become visible in the data processed using ASCRIBO’s unsupervised learning algorithm.

Under conditions where the outer raceway is stationary and the inner raceway rotates, the discrete impulses generated by a localized fault (pit) on the inner raceway were detected in a modulated form. This modulation occurs due to periodic changes in the relative position of the fault relative to the sensor, which distinguishes this signature from the outer raceway fault discussed earlier.

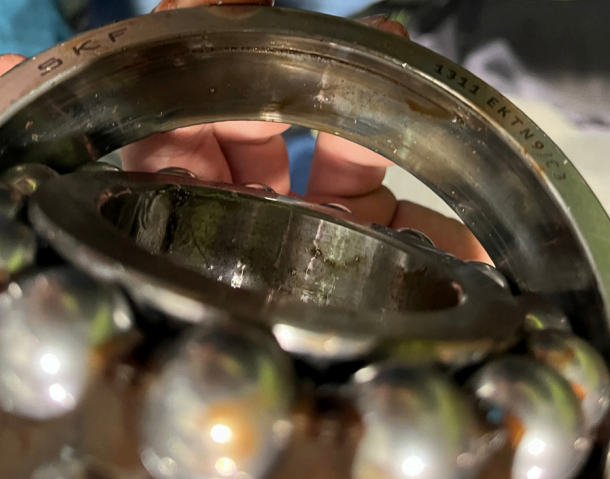

Figure-7: The disassembled bearing (operating at 2650 rpm) shows evidence of distributed surface damage and localized faults.

As mentioned in the first section, the early detection of this bearing failure (caused by the angular load resulting from fan imbalance) prevented unplanned downtime.

When the bearing was disassembled for maintenance during a planned shutdown, a fault spread over the surface was observed on the outer raceway, while a localized fault was found on the inner raceway. The support bearings and the fan rotor were replaced. Following the replacement, a decrease in overall vibration levels (mm/s) was observed on all three axes, and the bearing fault trends returned to normal.

Headquarters

11417 IRVING PARK RD IL-19 Suite B 13-7 FRANKLIN PARK, ILLINOIS 60131-3882 USA

+1 (224) 5810017